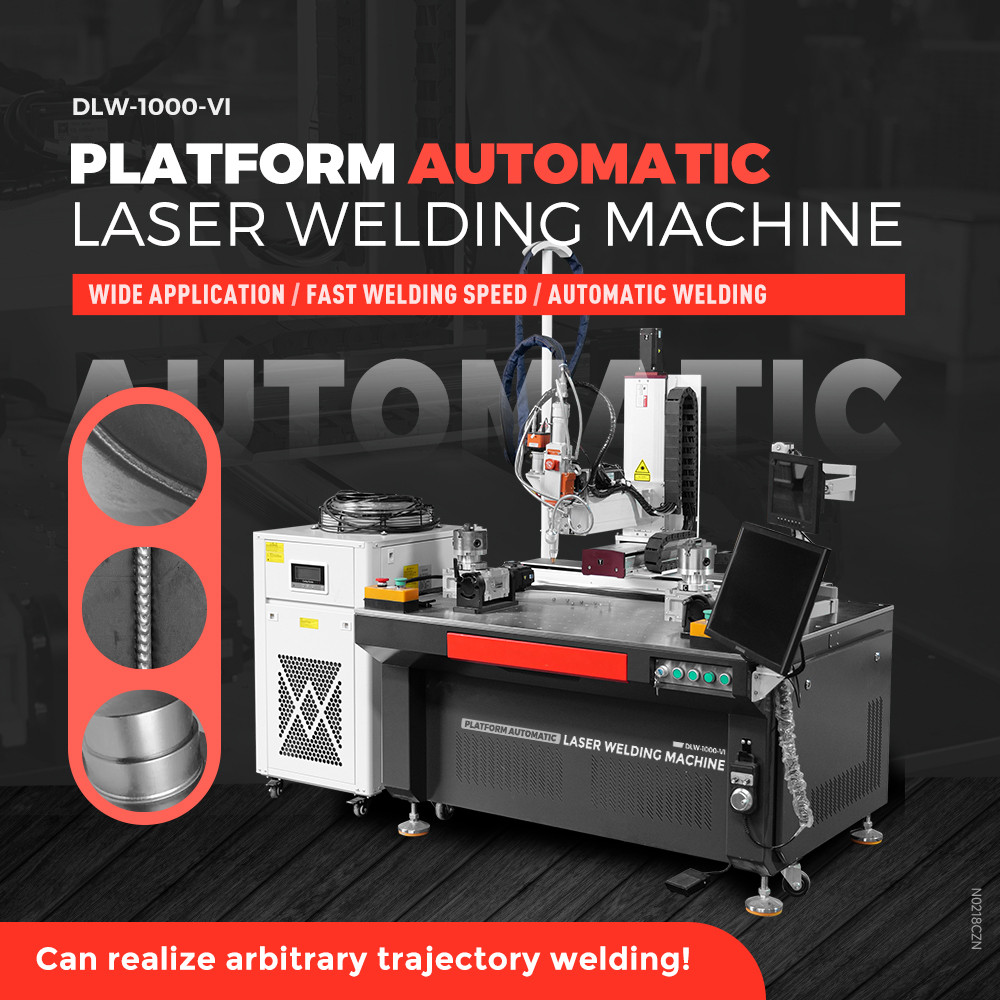

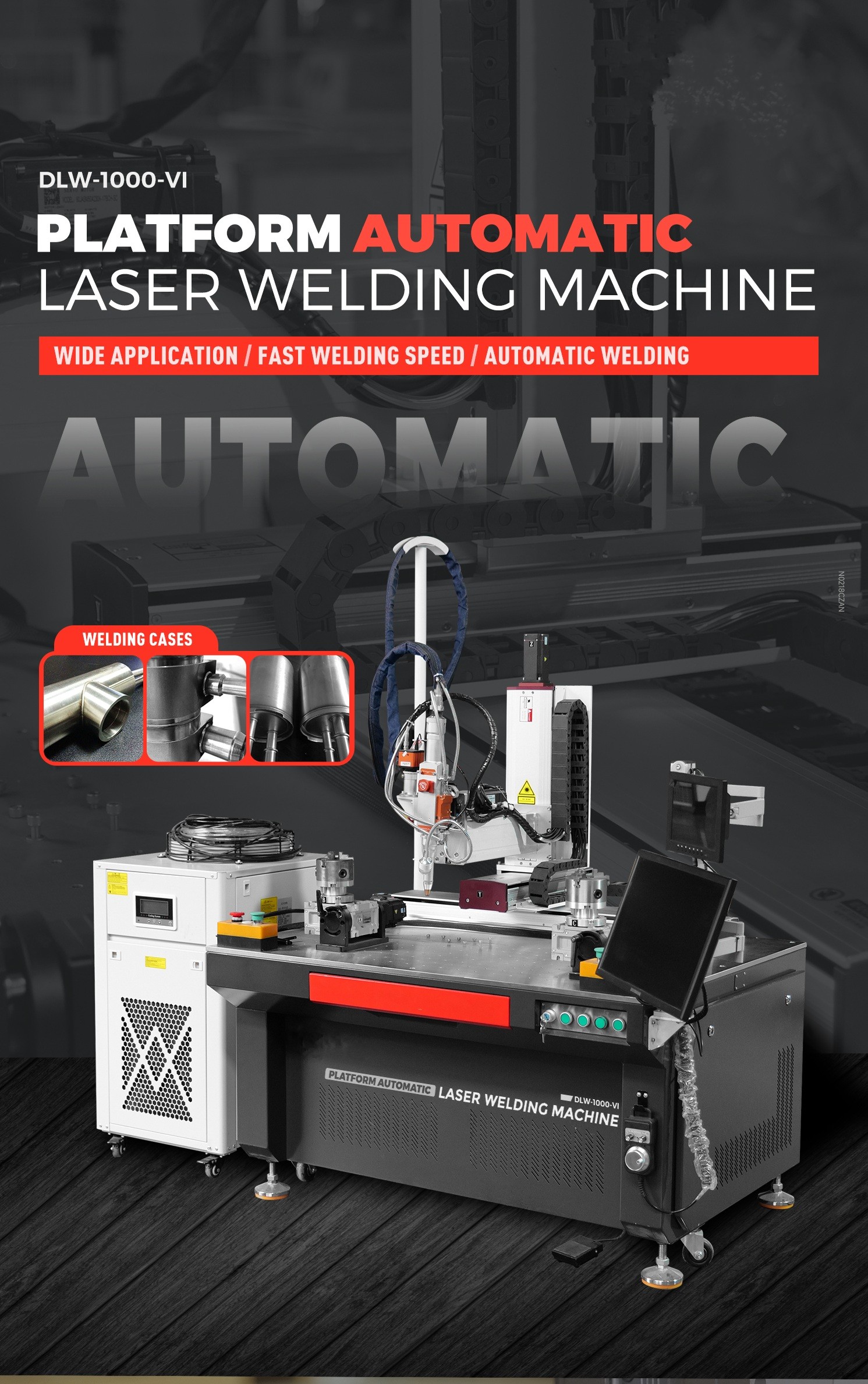

1000W 1500W 2000W 3000W Platform Automatic Laser Welding Machine Thin Metal Plate Laser Welder

$16,800.00 – $24,500.00

SKU: DLW-1000-VI, DLW-1500-VI, DLW-2000-VI, DLW-3000-VI

Categories: Laser Welder & Cleaner, Laser Welding Machine

Tags: metal-laser-welder, metal-laser-welding-machine, thin-metal-plate-laser-welderProducts

-

-

2000W 3000W 6000W 1530 Metal Sheet and Tube Fiber Laser Cutting Machine

$55,299.00 – $73,199.00 -

Product Parameters

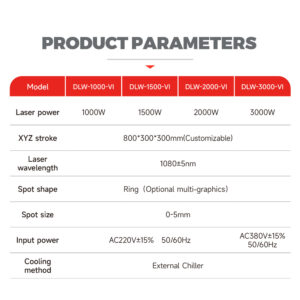

- Model:DLW-1000-VI, DLW-1500-VI, DLW-2000-VI, DLW-3000-VI

- Laser Power:1000W, 1500W, 2000W, 3000W

- XYZ Stroke:800*300*300mm(Customizable)

- Laser Wavelength:1080±5nm

- Spot Shape:Ring(Optional multi-graphics)

- Spot Size:0-5mm

- Input Power:AC220V±15% 50/60Hz AC380V±15% 50/60Hz(3000W)

- Cooling Method:External Chiller

Features and Advantages:

- Intelligent Design, fully automatic welding meet your various needs.

- Beautiful weld seam, firm and fast. Less polishing and grinding, better work efficiency.

- Maintenance free. Modular desgin for the whole machine, stable performance.

- Easy to operate. Simple operation, low cost and low requirements for workers.

- Wide application. Wide range of applications, high precision, fast

- High power. High aspect ratio of the weld seam, small heat-affected area, small deformation, fast welding speed.

- Long service life. Newly laser technology. The service life can reach more than tens of thoousands of hours.

- Can realize arbitrary trajectory welding, Can be done fully automatically or semi-automatic Weld metal workpieces with arbitrary trajectories such as points, straight lines, and arcs.

- Laser welding can realize spot welding, butt welding, stitch welding, sealing welding, and otherwelding modes for thin-walled materials and precision parts. Combined with aiming combination desgin, visual CCD acquisition, integrated infrared sensor to ensure accurate positioning.

- Multi-Axis Servo Welding Table. High positioning accuracy, sensitive response, shockproof design, no need to move the product manually, automatic movement for welding.

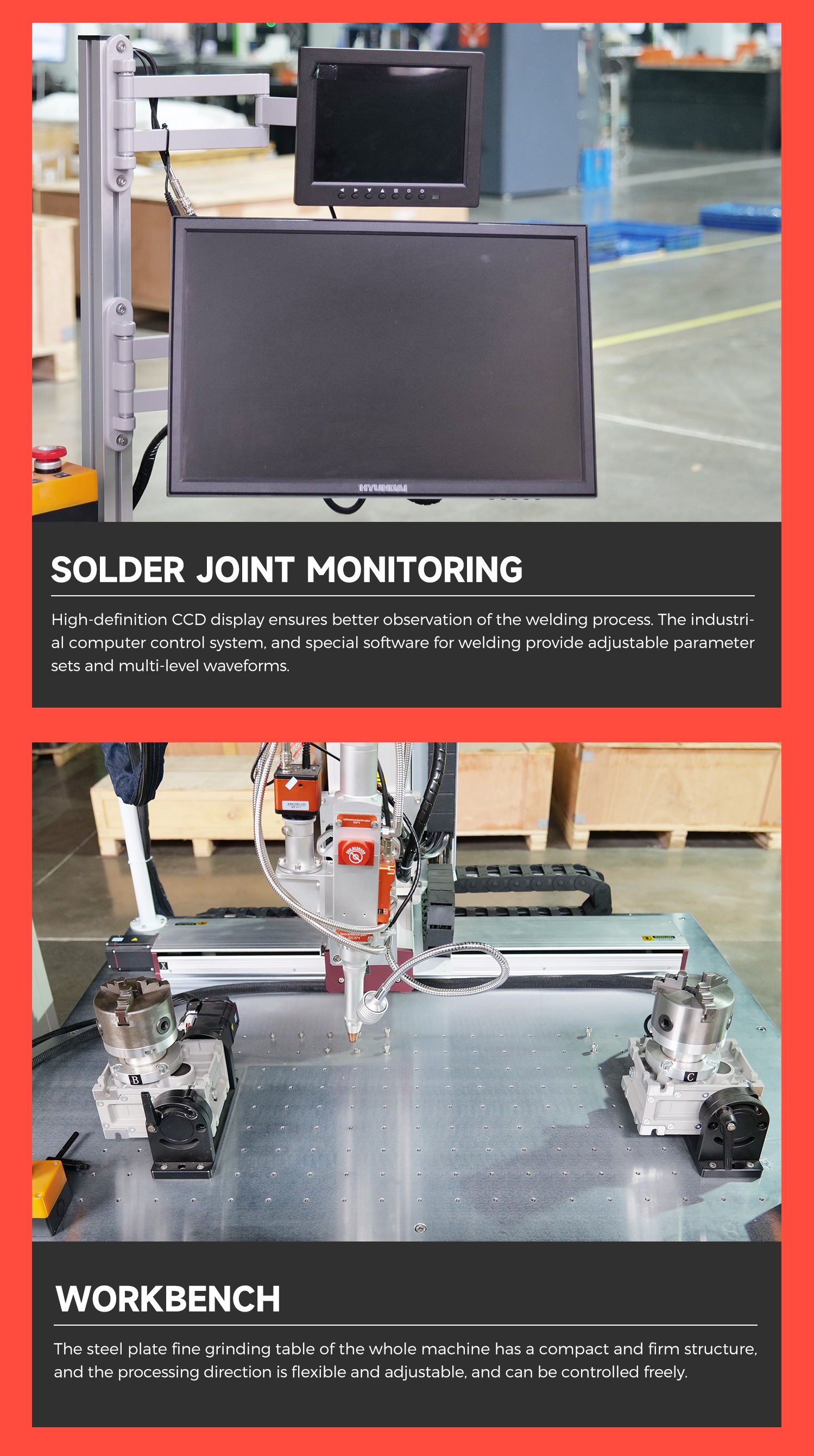

- Solder Joint Monitoring. High-definition CCD display ensures better observation of the welding process. The industrial computer control system, and special software for welding provide adjustable parameter sets and multi-level waveforms.

- Workbench. The steel plate fine grinding table of the whole machine has a compact and firm structure, and the processing direction is flexible and adjustable, and can be controlled freely.

Application and Warranty:

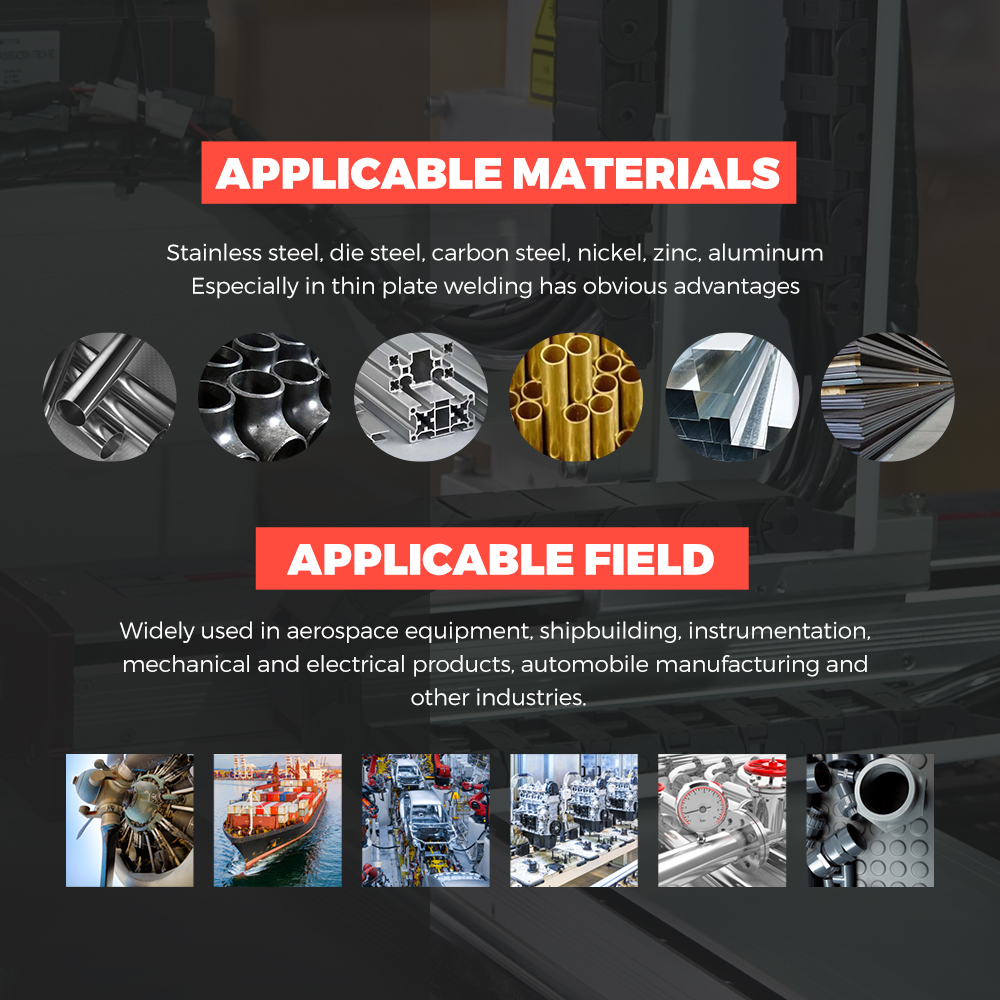

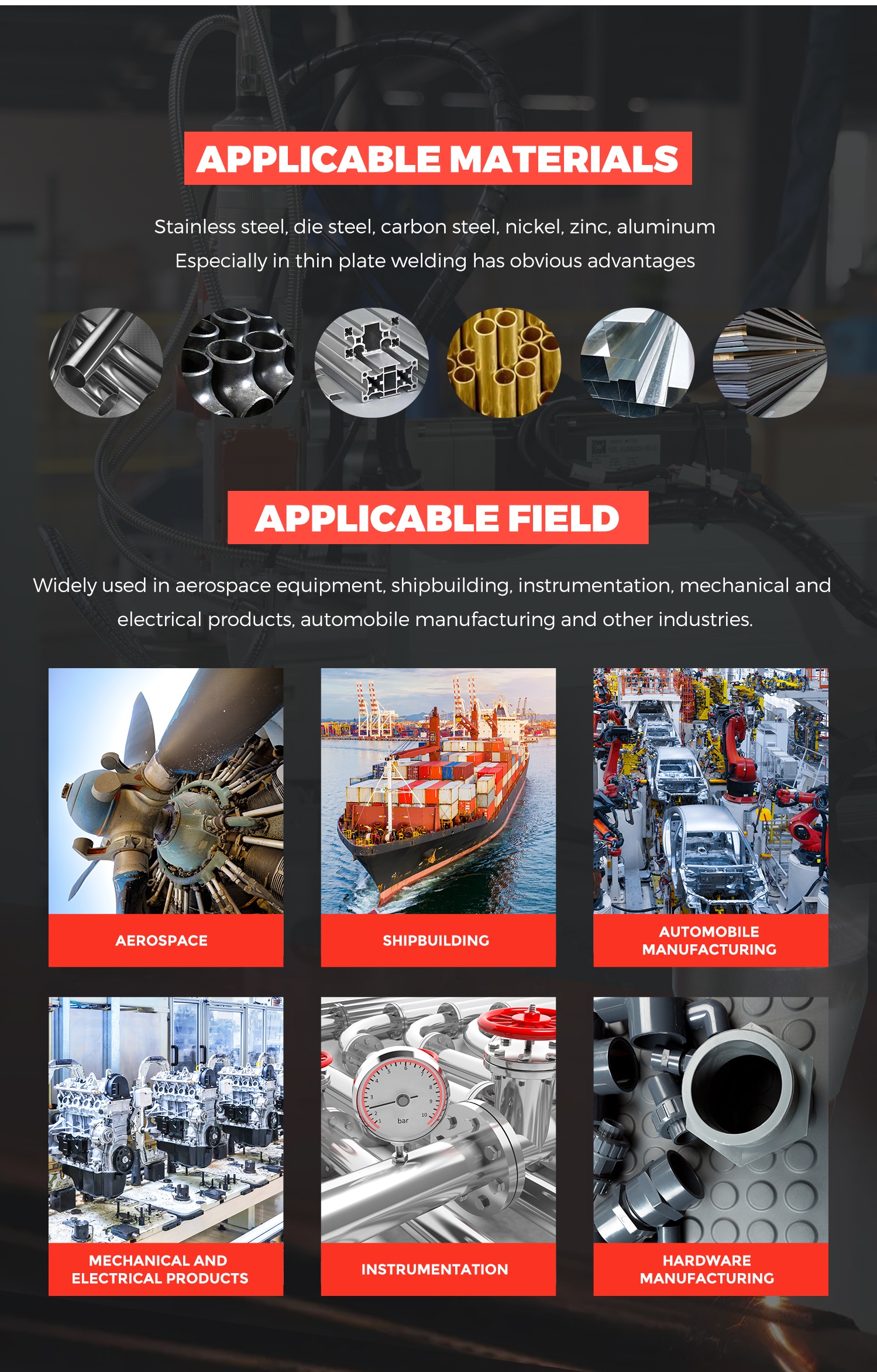

- Applicable Materials: Stainless steel, die steel, nickel, zinc, aluminum. Especially in thin plate welding has obvious advantages.

- Applicable Field: Widely used in aerospace equipement, shipbuilding, instrumentation, mechanical and electrical products, automobile manufacturing and other industries.

- One year for the whole machine, two years warranty for the laser source.

- Offer Remote Assistance. Free Shipping by Sea, No Import Duty for American Customers.

| power | 1000W, 1500W, 2000W |

|---|